Unsafe states in the Cartpole system

During the swing-up of this Cartpole system, a strong acceleration of the cart is required in both directions. To ensure the safety of both the hardware and the people standing next to it, it is important to test the safety of the system. The term “safety” assumes that the position of the cart does not exceed the physical limits of the rail at any time during the swing-up process.

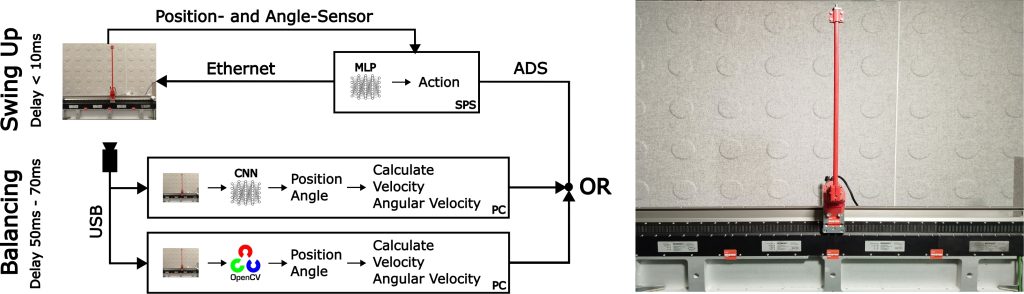

Due to the large delay caused by the image processing in controlling the cart to balance when using the video as input, a different model to the sensor-based balance model is used. This different behavior of the two controls and the resulting hard transition between angle-based and video-based balancing also requires TraceTube to analyze the safety of the system. The term “safety” in this case implies not only that the carriage does not exceed the physical limits of the rail, but also that the pendulum remains in the upright position during this transition phase.